Medium Voltage Engineering Design Services and Consulting

Medium voltage electrical solutions ensure safety, reliability, and efficiency in electrical systems, minimizing risks and enhancing operational performance across various sectors.

Medium voltage electrical solutions refer to electrical systems and services that operate within a voltage range typically between 1 kV (1,000 volts) and 35 kV (35,000 volts). These solutions are essential for the distribution and management of electrical power in various applications, including industrial, commercial, and utility environments.

Medium voltage electrical solutions refer to electrical systems and services that operate within a voltage range typically between 1 kV (1,000 volts) and 35 kV (35,000 volts). These solutions are essential for the distribution and management of electrical power in various applications, including industrial, commercial, and utility environments.

Key Components:

- Cable Installation and Maintenance: Involves the installation, replacement, and maintenance of medium voltage cables, both underground and overhead.

- Transformers and Switchgear: Includes the installation and replacement of transformers and switchgear, which are critical for voltage regulation and electrical distribution.

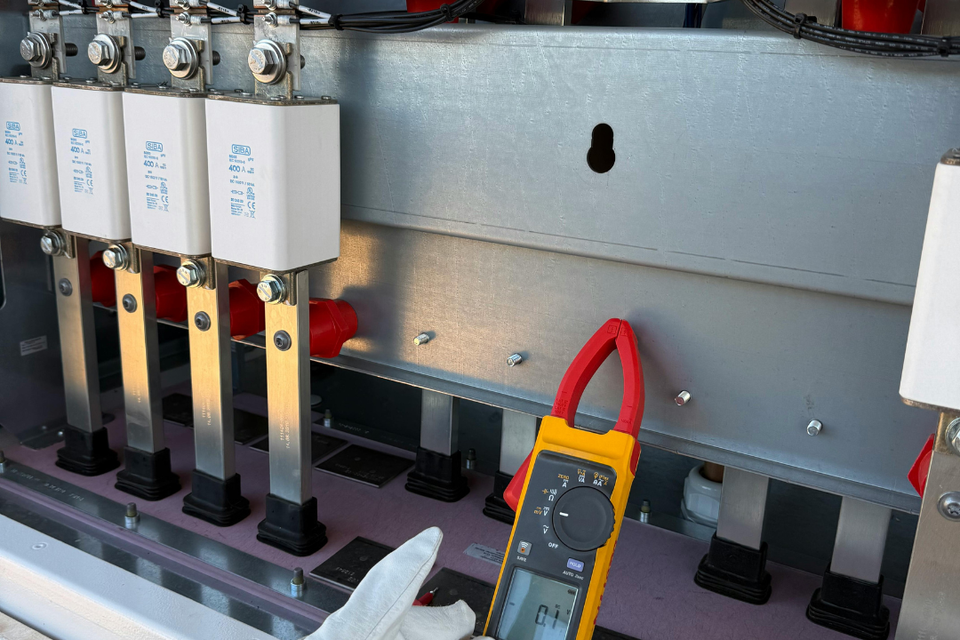

- Testing and Diagnostics: Encompasses testing methods such as VLF testing, partial discharge testing, and infrared thermography to ensure the reliability and safety of medium voltage systems.

- Engineering Design and Consulting: Provides expert guidance and design services to optimize medium voltage infrastructure for specific application

Applications:

- Power Distribution: Medium voltage solutions are crucial for distributing electricity from substations to end-users, ensuring efficient energy delivery.

- Industrial Facilities: These solutions support machinery and equipment that require reliable power at medium voltage levels.

- Renewable Energy: Medium voltage systems are often used in renewable energy applications, such as solar and wind, to connect generated power to the grid.